Quality Control for LED Products with StellarNet SpectroRadiometers

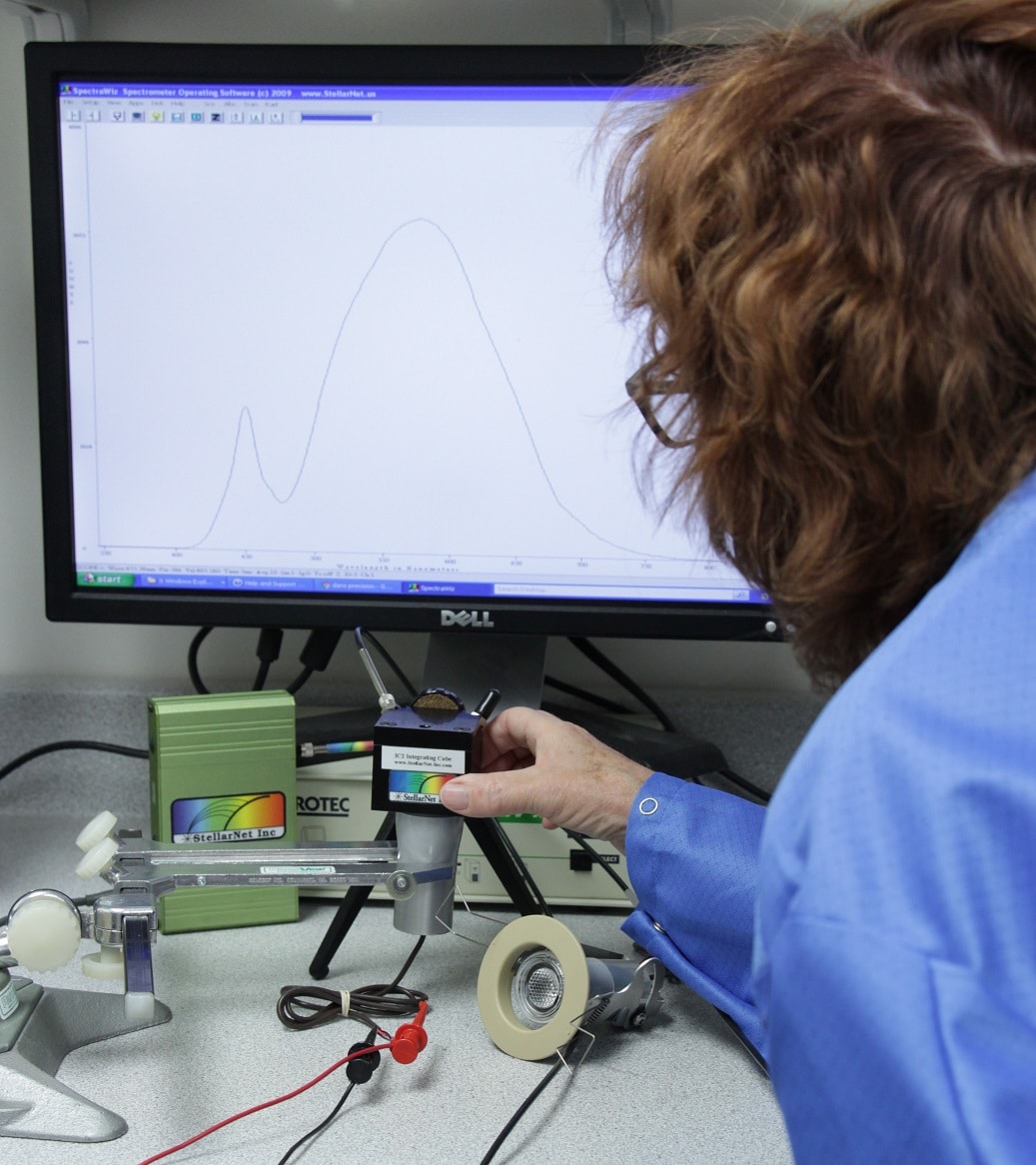

A StellarNet SpectroRadiometer enables DelphiTech to ensure quality, quantify new products and analyze competitive products. Rodney McInnis, CEO of DelphiTech, has been manufacturing high-end LED lighting for the outdoor home lighting industry for over 15 years. Almost ten years ago, he saw a demo of a StellarNet GREEN-Wave miniature Low Cost Fiber Optic Spectrometers 350-1100 nm, and bought that exact system for ~$2,500. His uses included color measuring, light output, and measuring scotopic versus photopic intensity.

“If I were going to buy a spectrometer today, why look anywhere else?”

– Rodney McInnis, CEO

The Show Floor Demo Sold It

In 2009, Rodney McInnis was attending LightFair International in New York City. The company had been manufacturing LED products since 2001, but with the LED competition heating up, and DelphiTech’s sales going up, ensuring quality became a top concern. Rodney met Jason Pierce of StellarNet on the show floor, and was impressed with the in-booth demonstration of the GREEN-Wave miniature Low Cost Fiber Optic Spectrometers 350-1100nm. “I left that show knowing I was going to buy that instrument,” Rodney says.

The in-booth demonstration sold him, and the ~$2,500 spectrometry system arrived. DelphiTech had ordered the GREEN-Wave Miniature Low Cost Fiber Optic Spectrometer, with a range of 350-1150 nm. A two-inch miniature integrating sphere with a ⅝” port also came, which was required for the LED xy Chromaticity testing that DelphiTech was interested in, as well as light output measurements.

“Our product is high-end. Our contractors expect robust, easy-to-install lighting, and our customers demand long-life, high-quality systems.”

– Rodney McInnis, CEO

DelphiTech has used the GREEN-wave spectrometer during (1) Production of LED Products, (2) New Product Development and for (3) Competitive Analysis.

(1) Ensuring LED Product Quality

The spectrometer’s first role at DelphiTech was to ensure LED product quality. The quality of the light of the outdoor lighting product was of utmost importance, and couldn’t noticeably vary from product to product when it comes to multifixture wall illumination uses. The spectrometer was installed as part of the production process, spot-checking outgoing products for quality assurance. During production, product quality was ensured via:

- Color spectrum analysis and binning confirmation

- Light output and beam intensity with different lenses

- Spot checks of in-production products

- Quantification of component variances

- Uniformity of phosphor deposition on LED dye through angular spectral measurements

- Extraction of performance data for product specification sheets from a

NIST calibrated machine

(2) New Product Development

The second role of the spectrometer at DelphiTech was quality control with design evolution and variants. When a new lens or LED change was introduced, the spectrometer assured that the light quality was up to DelphiTech’s high standards. When new products were introduced, the spectrometer was the key tool for analyzing and reporting the specifications of the product:

- Pre-production qualification for NPI (New Product Introduction)

- Deriving our product specifications for new products

“The ability to take the scotopic measurements allows us to understand how the lights will be viewed at night. Once again, I was pleased with my decision to go with StellarNet’s product based on the technical excellence of both the product and their team.”

– Rodney McInnis, CEO

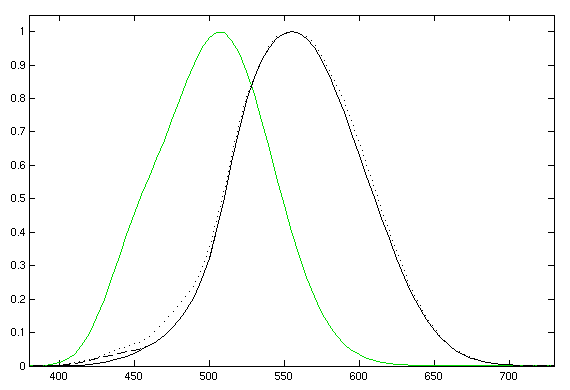

Scotopic (Low-Light) Measurements

Spectrometers are set up for photopic measurements by default, measuring color as a person would view it in bright light environments. However, the use case for outdoor LED lighting products was that they would be used in low-light settings, where the human eye shifts in sensitivity to a higher color temperature of white light – the scotopic vision of nighttime viewing. DelphiTech contacted StellarNet about the possibility to make scotopic measurements.The support team at StellarNet walked through a simple task of modifying a lookup table, to enable the instrument to make the necessary measurements.

The luminosity functions act similarly to a filter during light measurement – by adjusting the software on the Stellarnet Spectrometer, the light data will reflect how the organism perceives the particular light source. For nighttime illumination testing, the Stellarnet

Spectrometer’s lookup table can be adjusted to a scotopic condition. This is a key feature when testing outdoor illumination, either on houses or by streetlights.

(3) Competitive Analysis

After a few years, the competition in the LED space was getting crowded, and DelphiTech had to find a way to quantifiably differentiate their superior product from low cost and low quality products flooding the big-box stores via:

- Quantitative evaluation of other products’ performance

- Color spectrum analysis

- Light output and intensity

- Uniformity of phosphor deposition through angular spectral measurements

With LED production skyrocketing, and products flooding the market, proving the value of outdoor lighting products becomes even more important. “We do so many technical things to have high quality that our customers may not even know about,” says Rodney, detailing features like, “We include components and design features in each fixture specifically to protect from failure with nearby lightning strikes due to an induced EMP on the wiring – that is something I’m not aware of any other manufacturer doing.”

Indespensable Tool for LED Service Providers

The DelphiTech spectrometer also came with NIST traceable certification. “The spectrometer, and the NIST traceable standards, are an indispensable tools for any LED service provider,” Rodney adds.

About DelphiTech

In 2001, Rodney McInnis, an electrical engineer and physicist, not being satisfied with outdoor lighting products in stores for under eave/soffit mounted lighting, started designing an exterior LED lighting system for his own home that operated on 12VDC. Over the next year, he experimented with the latest in white light LED technology and UV stabilized polymer lenses to created a miniature light that would be robust in the perils of exterior conditions, from arctic conditions to the tropics, and mountainous regions to coastal. DelphiTech’s technical excellence in making some of the finest quality LED fixtures achievable is based on a no-compromise policy when it comes to the optimum design engineering, premium component selection, and detailed manufacturing quality.

DelphiTech has offered a time-limited Friends & Family discount to home-owner fans of StellarNet where they ship product. They’ve posted details at www.DelphiTech.com/STELLARNET should you or someone you know find this interesting.

Rodney McInnis, CEO

About StellarNet

StellarNet, Inc. manufactures NIST traceable LED and light measurement systems as part of our complete line-up of fiber optic spectroscopy instrumentation. All spectrometer systems are designed compact and rugged for a universe of applications from field portable measurements to space exploration. Or simply if you would like to have a long lasting compact spectrometer for your undergrad lab or for your Quality Control Department – Contact us today!

DephiTech’s products come in many variations, and create beautiful nighttime housescapes.