HortLED is introducing the ARC 600, a scientifically developed LED grow light designed for commercial cultivation.

“Commercial growers tend to focus on two points when selecting new lighting,” says Alex Bodell, founder of HortLED, “Plant performance and price. We were able to optimize the ARC 600’s light output and spectrum while balancing costs using data obtained via StellarNet’s BLUE-Wave spectrometer.”

The new ARC 600 is powerful, efficient, and (most important for commercial business growers), the ARC 600 sells at an industry-leading price. The ARC 600 is approximately 30% less expensive than competing LED products while delivering a plant optimized spectrum and ideal PAR levels. The ARC 600 produces limited infrared heat, thereby reducing cooling load requirements and therefore lowering ongoing operating costs.

“LED technology is the future of CEA lighting. We’ve made significant advancements on design and price. We think the ARC 600 is the perfect transitional product for growers looking to start using LEDs.” For commercial greenhouse growing installations, saving 30% on upfront capital costs can translate to hundreds of thousands of dollars in savings. Coupled with government incentives to purchase LEDs, the business case for the

ARC600 is clear.

LIGHT IS LIGHT

One of the biggest challenges Alex faces is educating growers on the benefits of LEDs over legacy lighting technologies, such as High

Intensity Discharge (HID) and Fluorescents. “As LEDs became more popular for growing, companies marketed the idea that special LED spectrums could dramatically increase plant growth at lower intensity levels. This got growers excited, but the plants, not so much.”

“We’re able to use the BLUE-Wave spectrometer to benchmark the ARC 600’s light output against legacy technologies. This

information gives us the data to ensure that our lighting technology will outperform the growers current lighting system. Light is light,

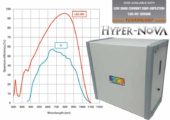

there is no secret formula when we can measure it with StellarNet’s BLUE-Wave.” The primary light for plant growth, described as Photosynthetically Active Radiation (PAR), falls within the visible spectrum range of light (400-700 nm). PAR is commonly measured with basic handheld meters. While these meters give the grower a general light intensity level, PAR meters do not display the spectrum of the light (shown at right) or detect wavelengths on either side of the visible spectrum. Alex and his team used the spectrometer during the design of the ARC 600 precisely because it captures spectrum data and reads electromagnetic wavelengths both inside and outside visible light. “Growers know that spectrum can have an impact on the size and shape of their plants. Being able to capture and share this data is critical for us.”

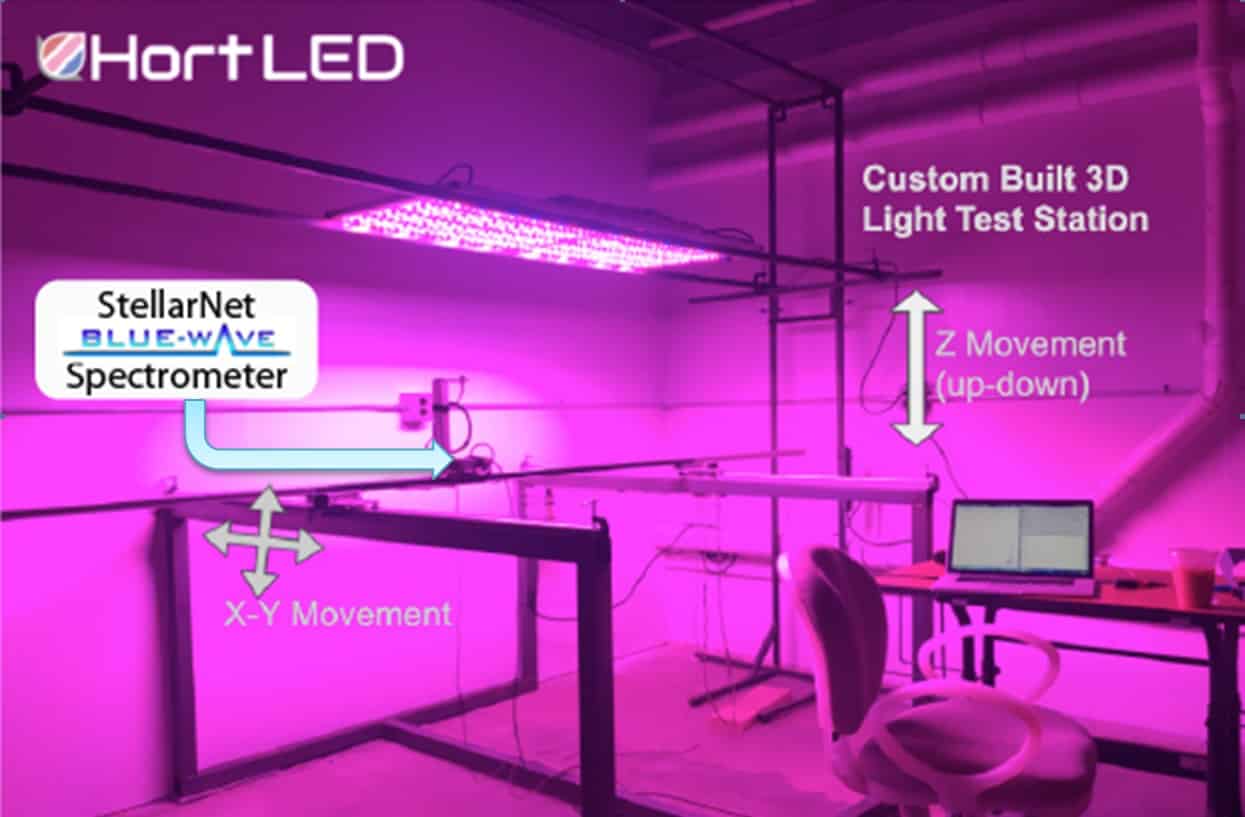

To help automate this process, Alex built a X-Y board (shown here) to automatically move the StellarNet BLUE-Wave miniature spectrometer, which is about the size of a paperback book and ruggedized to handle vibrations and movement without impacting performance. “We create incredibly precise PAR maps using the BLUE-Wave spectrometer,” Alex says, referring to an industry standard technique to identify the intensity of a lighting system over a fixed area. PAR maps are shown on the ARC600’s spec page, one of which is shown here – the yellow ‘star’ image – the X-Y grid of the measurement system is apparent on the 48-inch square map representation. The StellarNet BLUE-Wave Spectrometer, mounted on the X-Y board, and the SpectraWiz software were used to document the spectrum and intensity of the ARC 600. The BLUEWave detects electromagnetic radiation beyond the visible range (400-700nm). Light in the infrared range of 700-1000nm can be beneficial to plant growth or represent wasted heat.

History in Custom Product Development

In addition to lighting, HortLED creates custom indoor growing systems. Alex and his team have been designing and manufacturing controlled environment agriculture (CEA) systems since 2015. Projects have ranged from home consumer lighting products to large-scale indoor farms. For Grow NYC’s Project Farmhouse, HortLED designed and fabricated an 18′ long x 7′ tall x 2′ wide hydroponic system that was installed in their event space. HortLED also worked with MIT’s OpenAg initiative in the design, implementation and production of LED fixtures for a new controlled environment agriculture facility at Bates Lab. A consistent design requirement Alex has faced is being able to accurately communicate the PAR readings of his light fixtures. “By combining the BLUE-Wave with a custom fabricated the X-Y board, we’re able to generate the PAR data faster and far more accurately than other companies. “The system is shown in the pictures: top – HID lighting

system, middle – broad spectrum LED system, and below – targeted LED spectrum. Encouraged by the scientific and market developments, Alex’s team began an internal design process to produce their own CEA lighting system. Eighteen months of R&D led to the introduction of their first commercial product – the ARC600.

Seeking Distribution Partners HortLED is seeking distribution partners for the ARC 600. If you would like to evaluate or purchase the ARC600, or if you’d like to inquire about distribution partnerships, please contact Alex via his website: http://www.ARC600.com/contact