Asmaa Morsi… – Purdue University, Department of Horticulture

Abstract

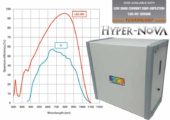

Astronaut diets on the International Space Station (ISS) depend on resupplied packaged food. However, missions to Mars of 3 – 5 years will not accommodate re – supply. In addition, many human macro and micronutrients degrade during long – term storage. Thus, growing nutritional plants aboard ISS is essential for providing astronauts with fresh, healthy produce. NASA is usin gan experimental vegetable – production unit called VEGGIE to grow fresh salad crops aboard ISS to provide astronauts with healthy diets. VEGGIE is a small plant – growth chamber designed as a garden for astronauts that is low in mass and has a low power requ irement. Veggie is equipped with light – emitting diodes (LEDs) but is exposed to the ISS cabin environment. Plants are grown with roots in a baked – ceramic substrate (arcillite) incorporating controlled – release fertilizer (Nutricote) and wicks delivering wat er by capillary action from a reservoir. The fertilizerprills release nutrients into arcillite slowly over time. Different controlled – release types have the same amount of fertilizer but release it over different time periods. The Purdue Mitchell lab in c ollaboration with NASA is testing growth of salad crops within VEGGIE analogs under ISS – like environments in a growth chamber. Specifically, we are evaluating effects of different controlled – release fertilizer treatments as well as different substrate part icle sizeson “cut – and – come – again” harvest scenarios, comparing productivity and quality of Lettuce as well as anAsian salad crop called Mizuna. ISS environments being mimicked include temperature: 24/21°C D/N, CO 2 : 2800 PPM D/N, RH: 45 – 50% D/N, and photoperiod: 16hours.Arcillitemedium contained one oftwo different fertilizer mixes: 7.5g18 – 6 – 8 T 70 + 7.5g 18 – 6 – 8 T100, or 7.5g18 – 6 – 8 T70 +7.5g 18 – 6 – 8 T180fertilizer/liter medium. LED Light treatment provides atotal PPFDof 330μmol m — 2 s – 1 PAR; with 270μm ol m — 2 s – 1 Red(R), 30μmol m — 2 s – 1 Blue (B), and 30μmol m — 2 s – 1 Green (G). Plants are grown under those conditions for 8 weeks, and harvested three times at 28, 42, and 56 days from planting. At each harvest, yield parameters as well as tissue mineral content have been measured for optimum fertilizer treatment selection.

Lettuce and Mizuna plants grown in a mix of 100% fine substrate particles (Profile) and fertilizer treatment of 50% T100:50%T70 had the higher yield as well as nitrogen contentcompared to those grown in 50%T180:50%T70. Growing mizuna plants in 100% profile resulted in higher shoot fresh weight; although no significant differences occurred for shoot dry weight. In addition, there was no significant interaction between substrate and fertilizer, which is reported by other research as one of the advantages of using controlled-release fertilizer