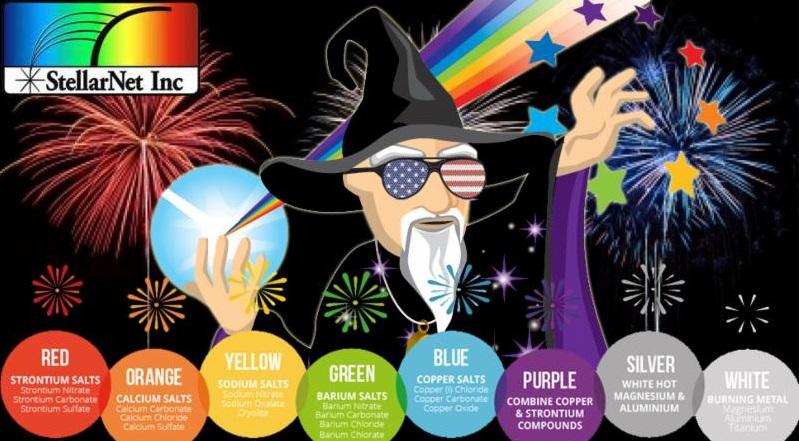

Let’s be frank: the most exciting part about chemistry is the explosions! A popular demonstration in General Chemistry class is the reaction between Al and Fe2O3, the thermite reaction. It needs a high temperature to get going, but the resulting reaction is so hot that the iron generated as a product is molten! In honor of our US Independence Day, here are some examples of researchers using StellarNet products while blowing things up.

Explosives as Biocidal Products

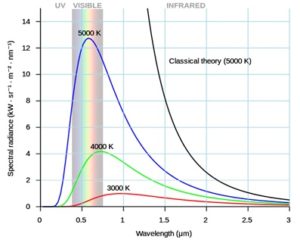

Speaking of thermite, the Dreizin group at the New Jersey Institute of Technology has combusted quite a lot of material (thermites included) using StellarNet products. Two of their studies looked at iodide compounds in metal composites as a possible biocidal product. The combustion reactions release iodide gas, which would neutralize any biological threat present in the air. The first study looked at Alᐧ Bᐧ I2 and Mgᐧ Bᐧ I2 composites compared to pure boron [1]. The researchers flowed the composite powders into a CO2 laser beam to ignite, then examined the effects of adding turbulence after ignition. A BLUE-Wave spectrometer was used to calibrate the photomultiplier tubes used for detection. A second BLUE-Wave was used to collect the emission spectra which were compared to a blackbody model to extract temperature. Adding turbulence decreased the burn time for boron and decreased the temperature of all samples. Measuring the intensity of the flame and the temperature over time suggested a two stage combustion: first the boron boils, then a cloud of boron oxide forms that inhibits further combustion. Adding turbulence removed the cloud, allowing for faster burn times.

Speaking of thermite, the Dreizin group at the New Jersey Institute of Technology has combusted quite a lot of material (thermites included) using StellarNet products. Two of their studies looked at iodide compounds in metal composites as a possible biocidal product. The combustion reactions release iodide gas, which would neutralize any biological threat present in the air. The first study looked at Alᐧ Bᐧ I2 and Mgᐧ Bᐧ I2 composites compared to pure boron [1]. The researchers flowed the composite powders into a CO2 laser beam to ignite, then examined the effects of adding turbulence after ignition. A BLUE-Wave spectrometer was used to calibrate the photomultiplier tubes used for detection. A second BLUE-Wave was used to collect the emission spectra which were compared to a blackbody model to extract temperature. Adding turbulence decreased the burn time for boron and decreased the temperature of all samples. Measuring the intensity of the flame and the temperature over time suggested a two stage combustion: first the boron boils, then a cloud of boron oxide forms that inhibits further combustion. Adding turbulence removed the cloud, allowing for faster burn times.

The second study looked at Alᐧ Ca(IO3)2 and Bᐧ Ca(IO3)2 (thermites!) [2]. They performed three types of combustion experiments. First, they coated a wire with powder and heated it with a DC current. Second, they measured the emission of individual particles in an air/acetylene flame. Three, they laser heated compressed pellets. A BLUE-Wave was used to measure temperature in this study, as well.  The wire experiment revealed that boron’s ignition temperature (650K) was actually below the temperature that the wire began glowing. Aluminum’s ignition temperature was 1100K, after the wire began glowing. The flame experiment revealed that the average temperature over the burn time was similar for both metals, despite the different ignition temperatures. In the pellet experiment, the aluminum pellet ejected fragments that also combusted, while the boron pellet gave off fine streams of particles. The authors suggested that the difference between the metals is due to the liquid that boron oxide forms. This allows for movement of fine particles producing streams and increasing the burn rate. They also examined the chemical composition of the combustion products. Notably, they did not contain iodide, suggesting that it was released into the air as intended.

The wire experiment revealed that boron’s ignition temperature (650K) was actually below the temperature that the wire began glowing. Aluminum’s ignition temperature was 1100K, after the wire began glowing. The flame experiment revealed that the average temperature over the burn time was similar for both metals, despite the different ignition temperatures. In the pellet experiment, the aluminum pellet ejected fragments that also combusted, while the boron pellet gave off fine streams of particles. The authors suggested that the difference between the metals is due to the liquid that boron oxide forms. This allows for movement of fine particles producing streams and increasing the burn rate. They also examined the chemical composition of the combustion products. Notably, they did not contain iodide, suggesting that it was released into the air as intended.

Combustion Properties of Metal Particles

The Dreizin group has also studied how different environmental condition affect the combustion of metal particles. For example, they studied how a water vapor environment affected the combustion of fine aluminum and magnesium particles [3]. Using water instead of natural gas in hydrogen production would eliminate CO2 emissions, so combustion in water needs to be understood. In this case, they found that water vapor led to longer burn times than previously found in the literature. The experimental results were verified by computational fluid dynamics simulations. These simulations were verified by a BLUE-Wave spectrometer by measuring the spacial temperature profile of a ceramic filament in the flame and comparing to the simulations.

Another study looked at how the turbulence conditions from above affected the combustion of aluminum and titanium [4]. A BLUE-Wave was again used to calibrate the photomultiplier tubes. For aluminum, the vapor tends to burn, while titanium burns on the surface. This led to some interesting differences. Both metals had shorter burn times with added turbulence, but aluminum was the shortest. The intensity of the flame decreased for aluminum and it was also a lower temperature. This is because the turbulence blew the burning vapor away.

Rockets!

Wilson, Jr. et. al. used StellarNet products to measure the intensity and hydroxyl radical generation of a hybrid rocket engine [5]. They used a BLACK-Comet with a cosine receptor to measure the overall intensity output of the plume and a high resolution UV spectrometer with a cosine receptor to quantify the hydroxyl radical concentration. The experiment was mostly a proof of concept that compact rugged spectrometers could measure rocket plumes, but they also generated some interesting results. First, the plume was horizontal and the radical concentration was higher below the plume than above it, indicating gravity affected the radical distribution. Second, a low oxygen flow rate led to more efficient combustion. Third, the highest radical concentration was 55mm away radially from the plume, which was not the brightest part of the flame.

Wilson, Jr. et. al. used StellarNet products to measure the intensity and hydroxyl radical generation of a hybrid rocket engine [5]. They used a BLACK-Comet with a cosine receptor to measure the overall intensity output of the plume and a high resolution UV spectrometer with a cosine receptor to quantify the hydroxyl radical concentration. The experiment was mostly a proof of concept that compact rugged spectrometers could measure rocket plumes, but they also generated some interesting results. First, the plume was horizontal and the radical concentration was higher below the plume than above it, indicating gravity affected the radical distribution. Second, a low oxygen flow rate led to more efficient combustion. Third, the highest radical concentration was 55mm away radially from the plume, which was not the brightest part of the flame.

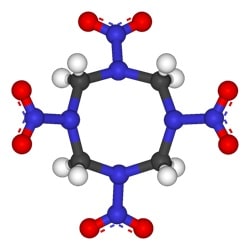

Shock Ignition of a High Explosive

Bassett and Dlott studied how an explosive responded to a high energy impact [6]. The explosive is called HMX, or octogen. The origin of the acronym is lost, but one speculative name is Her Majesty’s Explosive. To generate the impact, the authors used a laser to punch an aluminum disk out of a foil with enough force to ignite the HMX. They used a StellarNet radiometric standard to calibrate their radiometric measurements. Temperature was estimated from the spectra with a graybody model. On the nanosecond time scale, there was a spike in radiance with a temperature of 6700K, followed by a second, lower temperature spike on the microsecond time scale. When the speed of the disk was increased, the radiance for the nanosecond peak increased, but the temperature did not. This suggests that the impact caused small hot spots within the material to form which spread until the material exploded. Higher speed means more hot spots, but with similar temperatures.

Bassett and Dlott studied how an explosive responded to a high energy impact [6]. The explosive is called HMX, or octogen. The origin of the acronym is lost, but one speculative name is Her Majesty’s Explosive. To generate the impact, the authors used a laser to punch an aluminum disk out of a foil with enough force to ignite the HMX. They used a StellarNet radiometric standard to calibrate their radiometric measurements. Temperature was estimated from the spectra with a graybody model. On the nanosecond time scale, there was a spike in radiance with a temperature of 6700K, followed by a second, lower temperature spike on the microsecond time scale. When the speed of the disk was increased, the radiance for the nanosecond peak increased, but the temperature did not. This suggests that the impact caused small hot spots within the material to form which spread until the material exploded. Higher speed means more hot spots, but with similar temperatures.

While holidays like Independence Day only come once a year, science happens every day. There doesn’t have to be a special occasion to cause a few explosions. StellarNet’s products are more than rugged enough to handle the job of measuring them, too. Just remember, safety is also a part of science.

References

1. Wang S, Schoenitz M, Dreizin EL. Combustion of Boron and Boron-Containing Reactive

Composites in Laminar and Turbulent Air Flows. Combust Sci Technol. 2017;189: 683–697.

2. Wang S, Liu X, Schoenitz M, Dreizin EL. Nanocomposite Thermites with Calcium Iodate

Oxidizer. Propellants Explos Pyrotech. 2017;42: 284–292.

3. Corcoran A, Mercati S, Nie H, Milani M, Montorsi L, Dreizin EL. Combustion of fine

aluminum and magnesium powders in water. Combust Flame. 2013;160: 2242–2250.

4. Wang S, Mohan S, Dreizin EL. Effect of flow conditions on burn rates of metal particles.

Combust Flame. 2016;168: 10–19.

5. Wilson E, Keller B, Harkness K, Smeal C, Easterly M, Mackey J. Ultraviolet-Visible

Spectrometry Characterization of Combustion in Hybrid Rocket Motors. 42nd

AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit. Reston, Virigina: American

Institute of Aeronautics and Astronautics; 2006. doi:10.2514/6.2006-4343

6. Bassett WP, Dlott DD. High dynamic range emission measurements of shocked

energetic materials: Octahydro-1,3,5,7-tetranitro-1,3,5,7-tetrazocine (HMX). J Appl Phys.

2016;119: 225103.